|

Bazhou Wanrunda High Technology Co.,Ltd

|

Square to square mill pipe making machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Description

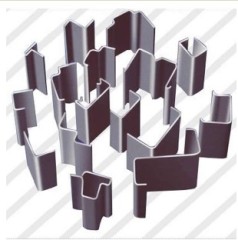

Principle: This machine is used to produce rectangular and square tube directly, not from round to square.

Direct square tube mill

The square/rectangular pipes(square tube making machine) production line adopts the combined roller and roller mat design. One set of roller can be compatible. The sharing rate of the roller is up to 80%. By adjusting roller mat, to reduce time on roll change and improve work efficiency, meanwhile this application also reduces investment on roll. At the same time the technology can save about 4% steel strip.

Technical parameter: Raw material:

Model | Material | Width | Thickness | Forming speed |

LW300 | Carbon steel | 300mm | 1.0~4.0nn | 20~50m/min |

LW400 | Carbon steel | 400mm | 2.0~5.0mm | 10~30m/min |

LW600 | Carbon steel | 600mm | 2.0~6.0mm | 10~25m/min |

LW800 | Carbon steel | 800mm | 3.0~8.0mm | 10~20m/min |

LW1000 | Carbon steel | 1000mm | 3.0~10.0mm | 5~15m/min |

LW1200 | Carbon steel | 1200mm | 4.0~12.0mm | 5~10m/min |

LW1600 | Carbon steel | 1600mm | 6.0~16.0mm | 5~10m/min |

LW2000 | Carbon steel | 2000mm | 6.0~18.0mm | 5~10m/min |

Description

Principle: This machine is used to produce rectangular and square tube directly, not from round to square.

Advantage:

1. By combined rolls, many size of rectangular and square tube can be shared with one set of roller. It can save cost on roller and reduce time on exchanging roller. .

2. Good appearance, better angle of rectangular and square tube.

3 By advance multi-point bending, avoiding the axial force and ensuring the quality, meanwhile reducing power wastage and roll abrasion.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Square Pipe

Square Steel Pipe

Stainless Steel Square Pipe

Steel Square Pipe

Square Tube

Square Led

More>>

.jpg)